TD-01 Poly bag inserter packaging line

Bag inserter carton/box/Turnover box/wooden box vacuum sealer machine

video

FeaturesAdvantage Poly bag inserter compact TD-01automatically machine:

1>No box too big to handle

2>High autonomy & trouble-free production

3>Quick and easy film roll exchange.

4>Integrated automatic bag detection.

Standard equipped with a 15” HMI LCD, multicolour warning light and infeed conveyor with separator.

The TD-01 standard runs up to 8 c/min (depending on case sizes) with a maximum output of 14c/min with the fast machine option.

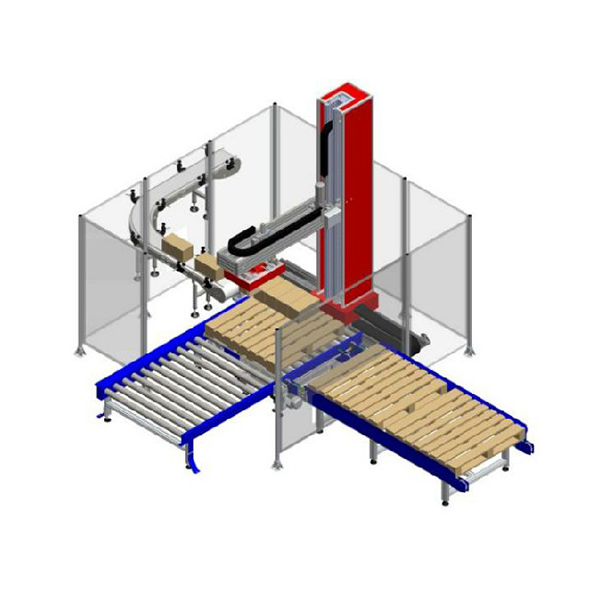

Combine with

Combine the TD-01 bag-in-box inserter with a Minstar case erector, weigh filler, bag closer , case closer and palletizer to profit from a fully automated bulk packaging line.

Containers

Multi footprint (L x W) with variable case heights.

Application area

This bag inserting machine is a perfect solution for specific needs and to pack specific products:

- Optimized bag insertion as required for crystallizing products such as cocoa mass or butter, CBS, fondant sugar.

- Use of different types of gusseted and non gusseted tubular film for paint powders & food ingredients.

- Use of multi-layer high barrier film for different applications.

- Insertion of two bags in one box (double liner)

About film

Film type:M Folded cylinder film

The bag inserter runs with made-to-measure bags or pre-made bags from a 40-60mm reel and handles multiple box footprints.

Film Benefits

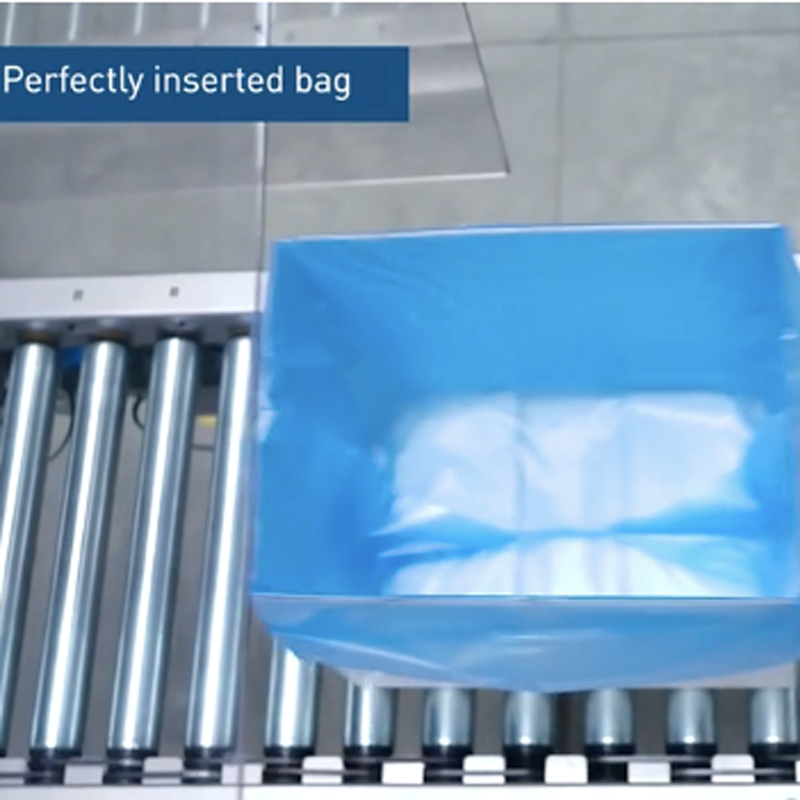

1.High performance & trouble-free production

Inserting bags perfectly up to 22 c/min.

2.Up to 4000 bags on one reel of PE-film for higher autonomy.

3.Elimination of operator mistakes thanks to the fully automatic format change.

4.Quick and ergonomic film roll exchange from the operator side.

Your intelligent bag inserter

>Inserting bags perfectly up to 14 cases/minute.

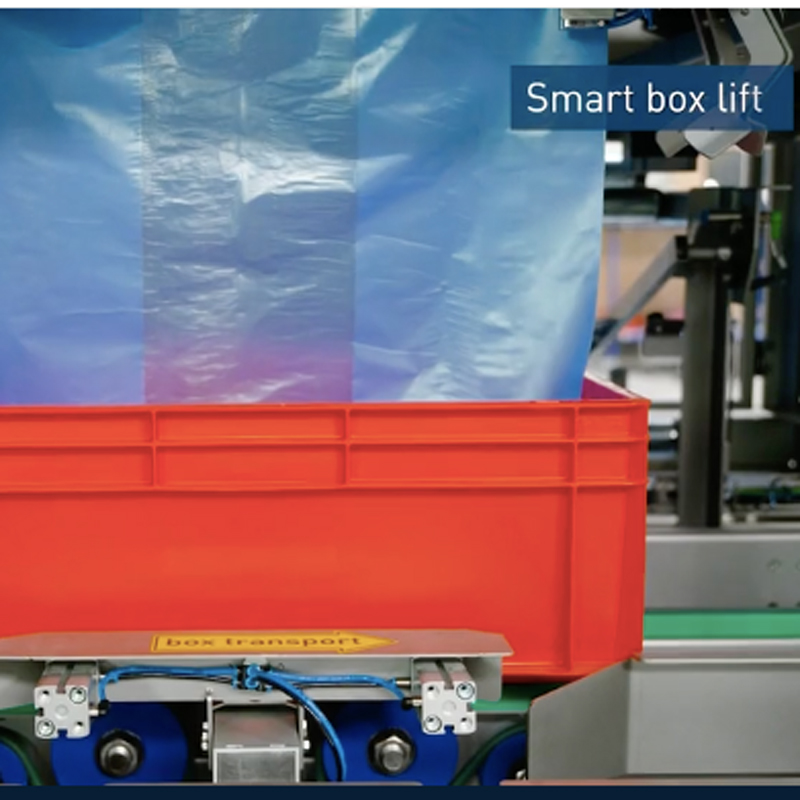

>Patented smart film opening technology.

>Quick and ergonomic film roll loading。

Failsafe bag opening thanks to the

- new strong gripper & spoon module

- patented smart film opening technology with a special vacuum & air insertion system

-Standard equipped with an integrated mechanical plunger, maintenance free V-shaped guillotine knife for a perfect film cut and a colour touch panel for easy operation.

Our machine for your carton packaging solution

Application area

Product parameters

| Case range: | L: 250mm(min)—500mm(max) W: 180mm(min)—400mm(max) H: 150mm(min)—550mm(max) |

| Speed: | Up to 4-15 cases per min. (standard machine)Up to 15 cases per min. (servo machine) |

| Bag materials: | 1.25 - 3.0 mils standard polyethylene films. |

| Voltage: | 220 VAC, 60 Hz, 3 Phase, or to local requirement. |

| Air requirements: | 80 - 100 PSI, 1/2” supply. |

| Finish: | Stainless steel frame, covers, contact parts and electricalenclosure. Internal components anodized aluminum, stainless steel and plated. |

| Machine handling: | To requirement, right to left or left to right. |

FEATURES BENEFITS

| Stainless steel finish. | Clean and durable, maintains hygiene. |

| Tamps out excess air. | Sealed bag fits the volume of the case. |

| Heavy duty design. | Suitable for demanding applications at low maintenance. |

| Full interlocked guarding. | Operator safety and OSHA compliance. |

Shanghai Min Star Packaging Machine Co,LTD

Taisheng ParkXingye StreetTaicang CityJiangsuChina

Phone/whatsapp: +86-18626223610

nina.tang@aliyun.com